- Welcome to Accuthermo Technology Corp.

- A Total Thermal Solution Provider

Part Number

Rating

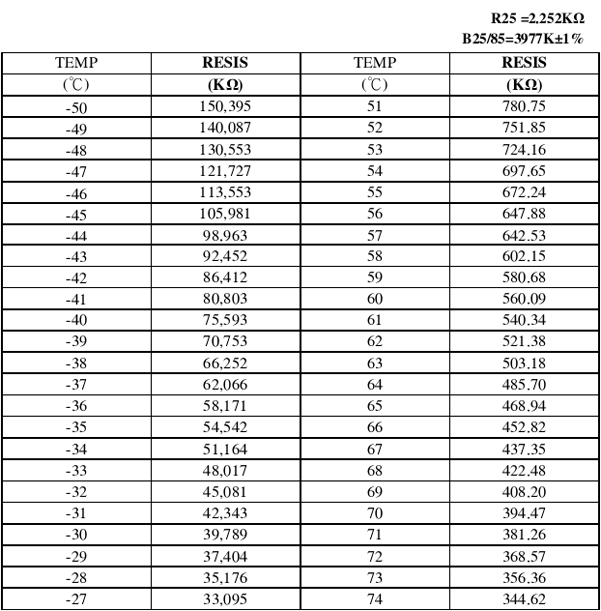

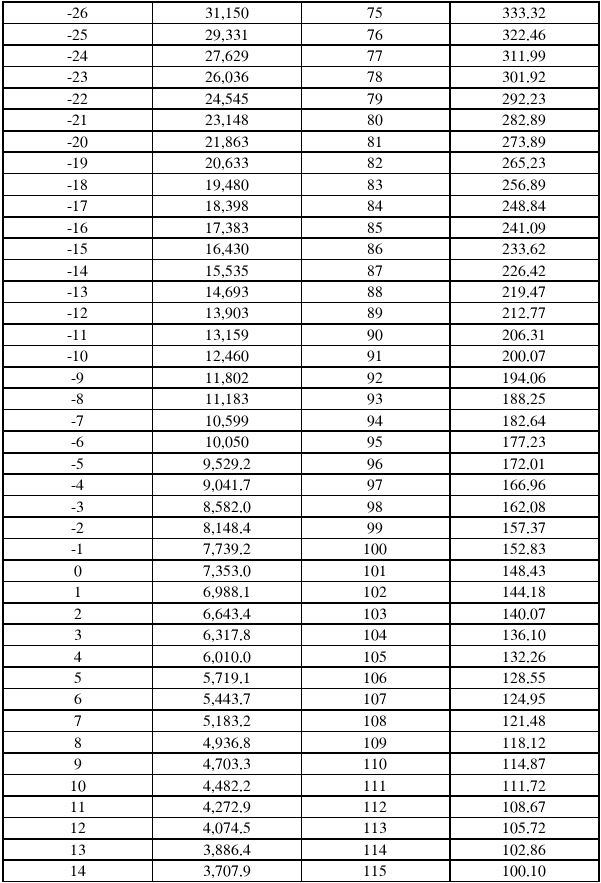

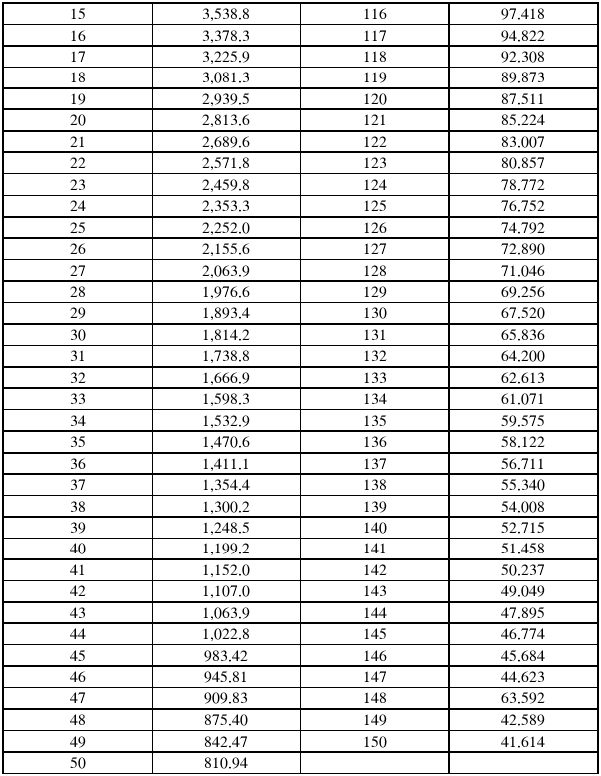

3-1) Rated zero-power resistance R25 : 2.252 KΩ NOMINAL

3-2) B value. B25/85 : 3,977 K ± 1 %

*The B value is calculated using the zero-power resistance values measured at 25 °C and 85°C.

3-3) Temperature coefficient @25°C : -4.4 %/°C

3-4) Dissipation factor. : Approx. 0.5 mW/°C (in air)

3-5) Thermal time constant. : Approx. 0.4 s (in air)

3-6) Toleauce range (tolerance) : 0°C to 70°C (±0.1°C)

3-7) Maximum operating temperature : 150 °C

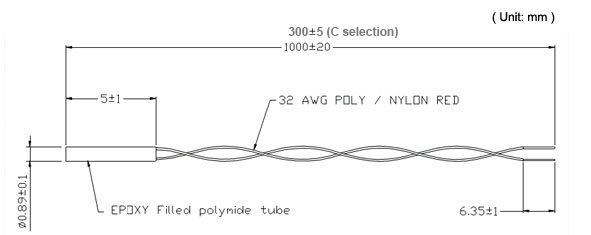

Dimension (mm)

Insulation

between epoxy resin and soldered terminals

5-1 Dielectric withstanding voltage : AC 100V for one second.

5-2 Insulation resistance : Above 100 MΩ at DC 500V.

Climate Tests

6-1) Dry Heat

After the test samples were exposed in air at 100°C for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

6-2) Damp heat

After the test samples were exposed in the humidity of 95% at 40°C for 1,000 hours,the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

6-3) Cold

After the test samples were exposed in air at 0°C for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

6-4) Humidity load

After DC 1mA current was applied to the test samples in the temperature of 40°C and the humidity of 95% for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

6-5) Change of temperature

One cycle of the change of temperature shall be carried our in the order of the following conditions.

Room ambient temperature.(Initial value)

At -30°C, for 30 minutes.

Room ambient temperature, for 3 minutes.

At + 80°C, for 30 minutes.

Room ambient temperature, for 3 minutes.

After 100 cycles of change of temperature, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

Mechanical Characteristics:

7-1) Robustness of terminations

* Tensile to horizontal direction

Hold the thermistor body so that lead wire shall be horizontal. After 1 kg loading weight was applied to the lead wire horizontally for 10 seconds, there shall be no visible damage.

7-2) Free fall

After three times natural fall to a maple board from 75cm high, there shall be no visible damage.

R-T Characteristics

Download

TR2252 Spec AT102011

|

.png)

.png)

.png)

.png)